In modern manufacturing, the pursuit of high efficiency, high precision and low loss has become the core of corporate competitiveness. In the field of cutting processing, the control of tool temperature directly affects tool life, processing quality and production rhythm. Blade Cooling Spray, as a new generation of local cooling solution, is gradually replacing traditional coolants and becoming a key role in CNC processing and precision manufacturing.

As a professional B2B manufacturer, we know that cooling spray is not just a bottle of liquid, but also a solution to improve processing efficiency and brand value. This blog will take you to a comprehensive understanding of the role, trend and customization opportunities of blade cooling spray, helping brands to create differentiated competitive advantages.

1.The secret weapon for efficient cutting: How does blade cooling spray significantly extend tool life?

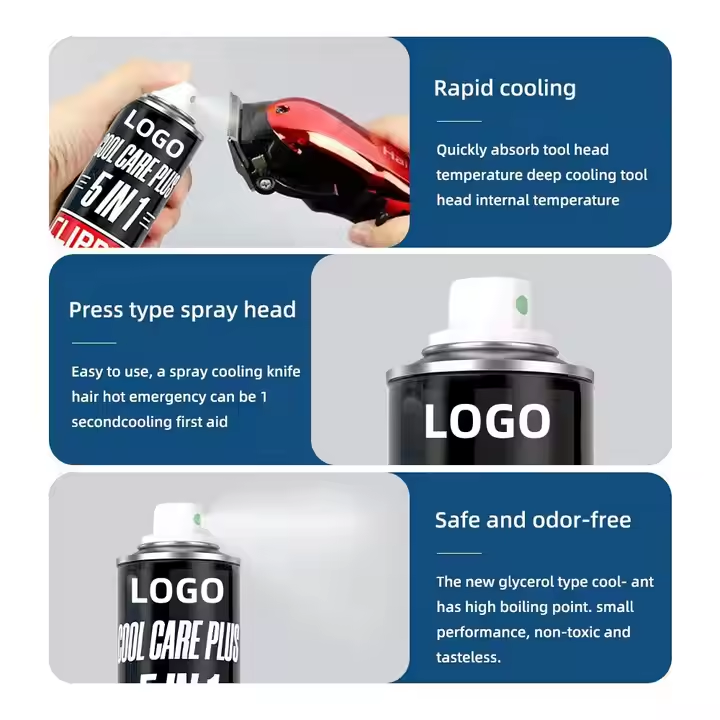

In the process of high-temperature and high-speed cutting, the tool surface is very easy to accumulate heat, causing thermal fatigue, increased wear and even chipping. The blade cooling spray can quickly cool down the cutting contact area, significantly reduce the temperature rise of the tool, and thus extend the tool life.

In addition to cooling, the lubricating components in the spray can also reduce the friction between the blade and the workpiece and reduce the cutting force. This combined effect not only protects the tool, but also improves the surface quality and overall process stability of the machined surface.

2.Why do more and more manufacturers choose customized brand blade cooling spray?

General cooling spray products are difficult to meet the increasingly diverse processing needs. Different metal materials, cutting parameters, and equipment types have different requirements for cooling effects, lubrication performance, and even evaporation speed. Therefore, more and more manufacturing companies are beginning to choose to customize their own exclusive blade cooling spray products.

The biggest advantage of customization is that the formula can be precisely formulated for specific processing scenarios to improve the use effect. At the same time, brand label exclusivity also helps companies build an independent market image and enhance user stickiness. For B2B customers who want to establish their own brands, customized cooling spray is becoming a key entry point for opening up niche markets.

3.The core role of blade cooling spray in metal processing and its application advantages

Blade cooling spray is widely used in the field of metal processing, especially in high temperature and high friction environments such as CNC precision processing, CNC milling, and automated turning, playing a vital role.

It can not only achieve local rapid cooling, avoid thermal deformation and surface burns, but also has good lubricity, rust resistance and anti-chip accumulation ability, effectively improving processing quality and equipment stability. Compared with traditional high-flow coolants, the spray method is more energy-saving and environmentally friendly, easy to use, easy to control and maintain, and more suitable for modern small-batch, diversified, and high-precision processing needs.

4.From heat dissipation to lubrication: Multiple performance analysis of blade cooling spray in CNC processing

High-performance blade cooling spray is not only a cooling tool, but also a multi-effect processing aid. In CNC processing, it also undertakes multiple tasks such as heat dissipation, lubrication, rust prevention, anti-chip accumulation and reduction of flying chips.

The lubricant in the spray can form an extremely thin lubricating film between the tool and the workpiece, reducing direct contact between the metals, thereby reducing friction and avoiding dimensional deviations caused by thermal expansion. At the same time, high-quality spray can also prevent cutting chips from adhering to the tool surface and improve cutting stability. Some spray formulas also have quick-drying and rust-proof functions, which can effectively avoid machine pollution and tool corrosion.

5.Blade cooling spray formula revealed: key elements for creating high-performance exclusive brands

The performance of blade cooling spray lies in its scientific and reasonable formula design. A high-quality spray formula usually contains ingredients such as cooling base fluid, lubricating additives, rust inhibitors, surfactants and environmental stabilizers.

The cooling base fluid determines the heat dissipation efficiency, and is commonly water-based, alcohol-based, oil-based, etc.; lubricants such as esters and silicone oils can enhance the surface protection of the tool; rust inhibitors are used for tool protection in long-term storage or humid environments; surfactants help the liquid to be sprayed evenly and improve permeability. Environmentally friendly additives are related to whether the product meets export standards and customer requirements for sustainability.

By customizing these formulas, we can create truly competitive blade cooling spray products for different process requirements.

6.Customized cooling spray solutions: Help B2B customers establish differentiated product lines

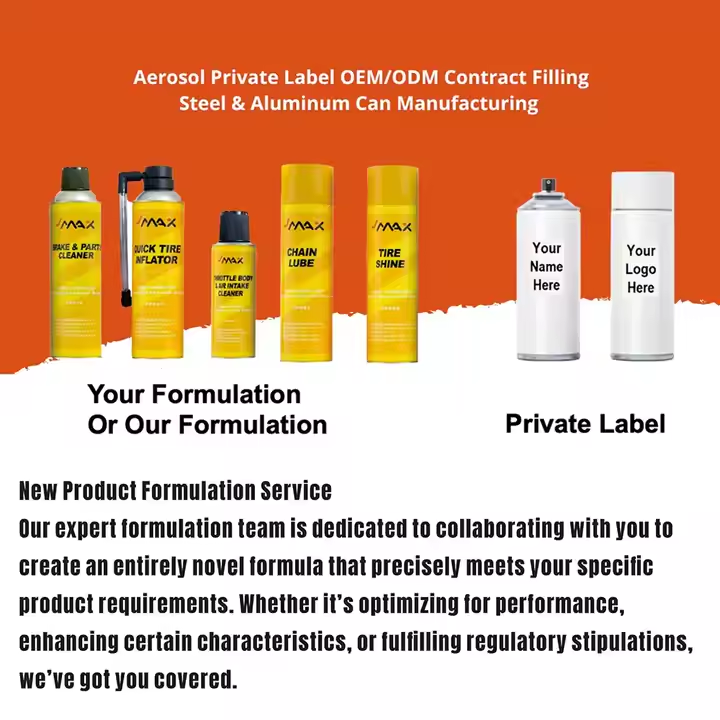

For B2B companies that want to build their own brands, customized blade cooling spray is not only a technical choice, but also a strategic layout. Through OEM/ODM cooperation, brands can quickly launch market-oriented products without building their own factories and seize the window of industry demand explosion.

We provide customers with a variety of customized cooperation solutions, including OEM, formula development + design services (ODM) and fast white-label cooperation. Customers can choose the most appropriate path to achieve product landing and market layout based on their own resources and brand strategy.

Customized cooling spray also means higher profit margins and user loyalty. Processing companies are often accustomed to using stable cooling spray products for a long time, with a very high repurchase rate, which lays a good foundation for brands to build long-term customer relationships.

7. Analysis of blade cooling spray market trends: new growth opportunities for manufacturing companies in 2025

According to market research institutions, the global tool cooling and lubrication market will continue to grow in the next three years, especially in the Asia-Pacific region. The rapid popularization of CNC and intelligent manufacturing will drive a large demand for spray cooling products.

Manufacturing companies are accelerating their transformation towards energy saving, high efficiency and environmental protection, which also brings broad market space for “new environmentally friendly cooling spray”. At the same time, with the enhancement of brand awareness, companies pay more attention to product differentiation and brand independence, and OEM/ODM customization needs are growing rapidly.

For B-end enterprises that hope to establish a competitive advantage in the industrial auxiliary materials market, now is the best time to enter the blade cooling spray track.

8.Why OEM/ODM customers prefer sustainable and environmentally friendly formulas for blade cooling spray

In the European and American markets, environmental standards are constantly improving, and traditional spray products containing high VOC (volatile organic compounds) are gradually being eliminated by the market. Environmentally friendly, water-based, and biodegradable cooling sprays have become customers’ preferred purchasing options.

We provide customers with environmentally friendly spray formulas that comply with regulations such as RoHS, REACH, and CA Prop 65, including non-toxic, odorless, zero-corrosive, and zero-residue water-based cooling sprays, helping brands to smoothly enter the high-end market.

Environmental protection is not only a regulatory requirement, but also the direction of long-term development of the brand. Choosing an environmentally friendly cooling spray can help enhance the brand image and win customer recognition, while also opening up high-threshold channels such as government procurement and overseas markets.

Conclusion: Build your own blade cooling spray brand now

Although blade cooling spray is an industrial auxiliary material, it has a profound impact on manufacturing efficiency, product quality, and corporate image. In an era of parallel development of precision manufacturing and green processing, the quality and brand of cooling spray products will directly affect customers’ purchasing decisions.

If you are looking for a reliable partner to help you build your own cooling spray product line from scratch, we are very willing to be your choice. Whether it is OEM, formula development or environmental certification, we can provide you with full-process, one-stop service support.

Welcome to contact us and start your own exclusive blade cooling spray brand!